Forty years ago, a gallon of gas was less than a buck, and for 20 cents, you could send a first-class letter across the country. MTV offered a new way to "watch" music, and the average 30-year rate on your home mortgage hovered around 16 percent. Ouch! In the world of BMW Motorrad in the early 1980s, the R 100 RT, the most expensive production motorcycle in the world, could be yours for about $6,500. It’s good to know some things, at least, have gotten better with time.

Long-time BMW MOA member Stuart Sorkin (#2307) of Anaheim, California, found his beloved 1982 R 100 RT at Ozzie’s BMW in 1995 and for the next 16 years rode the wheels off the bike, traveling to BMW rallies across the country. Then, in 2011 an unfortunate accident forced him to park the bike in his garage where it sat for the next six years. Sorkin felt sadness for the damaged Airhead every time he walked by it as it sat on a lift in his garage, just begging for new life. While Sorkin knew he didn’t have the time to bring it back to its original luster himself, he thought the MOA Foundation could. So, in 2017, he donated the bike to the Foundation, hoping they’d be able to use his ailing RT for something special. Little did he know just how special the bike would become!

The bike remained in a California storage facility until the summer of 2020, when MOA member Wendy Naessens introduced Zack Witkowsky to a key Foundation director. At the time, Witkowsky was looking for a project to transform into a rolling work of metal and rubber art and agreed to take on the BMW MOA Foundation project. Though neither party knew what the project would become, they knew something special was about to take place in a small shop in the little town of Beecher, Illinois.

When he agreed to take on the project, Witkowsky didn’t know the eventual purpose of the bike. Perhaps it would find a spot in the newly conceived museum at the MOA headquarters in Greer, South Carolina. Or maybe it could be restored and sold to generate much-needed Foundation income. In the end, it was decided the bike would be the basis for a complete restoration and the Foundation would use it as a future raffle bike.

project.

Though young by most Airhead standards, Zack had many years of both BMW Motorrad and BMW MOA experience under his belt. The son of long-time BMW MOA member and Airhead wrench Jeff Witkowsky, Zack was well-known in the Airhead community going back to the days when he was a fixture in his dad’s sidecar rig heading off to another rally somewhere.

Ready to win this motorcycle?

Visit the BMW MOA Foundation to find out more about the Completely Custom Bike raffle and your chance to win this motorcycle.

When he wasn’t in a sidecar watching the fields of corn and soybeans whiz by, Zack was usually found at his dad's side, handing him tools as the elder Witkowsky worked on motorcycles in his shop. By the time he was eight, Zack had successfully torn down his own motorcycle, a 1975 R 75 /6. His dad had given it to him, and Zack owned the motorcycle for nearly 25 years before finally outgrowing it and passing it on to his brother-in-law.

Once Zack was in his late twenties, Jeff slowly began handing the reins of Stable Sport and Touring to his son. However, the younger Witkowsky wasn’t yet in a position to leave the security of his full-time job and plunge into the unknowns of business ownership. Still, the two spent time together in the shop whenever they had the opportunity, and it was through working with his father that Zack developed the mantra that the work had to be right before a bike could leave the shop.

"They had a very special relationship that I feel privileged to have seen," Zack’s wife Jen said.

"There was very little English spoken, but through their grunts, nods, and glances, they could rebuild a bike. It was like watching a ballet."

Sadly, Jeff passed away in August of 2017, and Zack found himself alone in the garage where he had spent so much time working alongside his father. Still, Zack's dream of continuing the shop's legacy grew stronger, and with his wife, Black Wolf Touring and Custom was born.

Zack had only seen pictures of the distressed RT when he enthusiastically agreed to take on the project. That was probably a good thing, he recalled when the bike arrived at his shop.

“Based on the initial photos I received of the bike, I knew going into the project that the bike was a mess,” Zack said, “a full-on project.”

When the rolling chassis was delivered, it was accompanied by 10 or 11 boxes of differing sizes, including two full RT fairings, extra sets of wheels, fenders, a fuel tank, and many spare parts. Plastic bags covered exposed pistons. Mirrors hung from the handlebars, and the headlight bucket was empty. It reminded Zack of a scene in the original Jurassic Park movie where one of the characters enters the park and finds a large pile of dinosaur excrement. “That’s a big pile of s**t was the line spoken in the movie,” Zack said, “and also one of my first thoughts when I first saw it.”

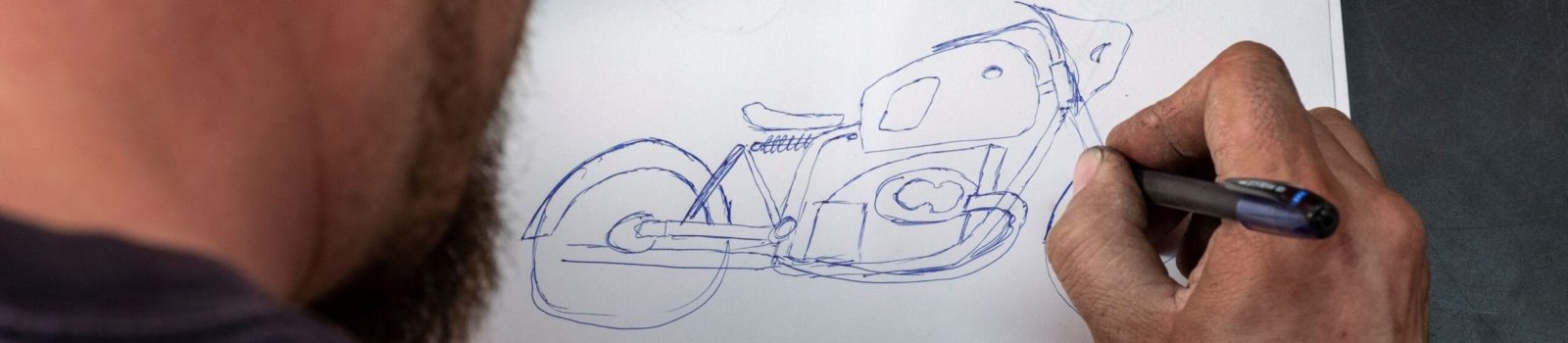

The goal was to build something appealing not only to long-time BMW aficionados but something of interest to his generation—the next generation of BMW MOA members. With that in mind, an idea Zack had carried for years of a monochromatic, silver-framed BMW cruiser with an unconventional rear suspension began to stir in his mind. The bike would include a taillight inspired by a 1950s-era Pontiac Chieftain, a ridge detail running over the front and back fenders and down the tank's length to give the illusion of being stretched. It would all be painted in a light metallic blue, a color Pontiac used on their engines when the Chieftain cruised the highways of America.

Undeterred by its torn and tattered condition, Zack wheeled the bike into the shop to access the task ahead and quickly realized that nothing less than a full nut and bolt build from the ground up was needed. But, before he could begin to build, Zack first had to tear it down.

Working from the top down, Zack began the project by pulling off all of the bike's electrical components, then the windshield, handlebars, controls and anything else he could remove until he ended up with nothing more than a rolling chassis. Disassembly complete, the real work of rebuilding could now begin.

To create what he had imagined for so long, Zack's first step and possibly the biggest hurdle of the build was the development and fabrication of the rear suspension. His plans included converting the RT’s original dual shock swingarm into a single shock system with the shock mounted horizontally and hidden under the seat. To do that, Zack first needed to design a structure able to transfer the vertical motion of the swingarm into the horizontal movement of the shock while working correctly with the existing drivetrain. With the help of suspension guru and friend Gordy Roth, the pair painstakingly worked on the necessary geometry until they were satisfied with the result. With that completed, a custom shock offering adjustability for ride height, spring preload, damping and rebound and high and low-speed compression was sourced from Penske Suspension.

suspension and horizontally-mounted and fully adjustable Penske shock can

be seen.

With the rear suspension receiving that much attention, the front end needed to offer the new owner similar adjustability and comfort. To accomplish that, the RT's original spring and plunger system was replaced with adjustable, self-contained cartridges, providing a fully adjustable front end to match the rear end.

Suspension work completed, Zack could now turn his attention to the fabrication of the front and rear fender mounts and the unique details added to the tank and rear fender. Zack said that the factory front fender and the engine's timing cover have a rib running down their centers. “I've never really liked that center rib and always thought it looked out of place, so I usually got rid of it by backfilling and working it out to create a smooth fender. But on this bike, I decided to work with it.”

"The rear fender is actually a front fender from a period police bike which I reversed and trimmed to size," he said. "Now, with two fenders and a timing cover with ribs, I decided to carry that feature to the fuel tank."

Zack believes the detail offers the impression that the motorcycle has been stretched, though it has the same wheelbase as the original RT. The detail also made it unnecessary to pinstripe the tank to highlight body lines, as the ridge would do that on its own.

The last frame modification was to build the seat mounting system. To do that, Zack designed a seat mount offering not only fore and aft movement but also seat angle adjustment. A solo saddle with a tuck and roll finish was fitted to the new mounts.

“I wanted to incorporate a comfortable, upright riding position similar to that of a Slash 2,” he said. “Ultimately, I’d like the rider to have the option of riding to a show 500 miles away while camping along the way. Then, once the owner won the show, riding the bike home again!”

"I didn't want to build a trailer queen," he continued, "I wanted to create a bike that gets ridden."

With frame modifications complete, the frame components were sent to his powder coater and finished in a Stardust silver, along with the wheels finished in Night Shimmer, a graphite silver color.

With that work complete, Zack finished his work on the tank and fenders and painted them in Pontiac Metallic Blue, which is also the color he used to accent the engine timing cover, cylinders and valve covers. It was now time to turn his attention to the engine.

When he first received the bike, plastic bags covered exposed pistons leading Zack to wonder what else he would find once he tore into the motor. What he found were broken rod bearings and issues with the front main bearing carrier and timing chain. In the end, the engine received a complete overhaul which included a new PowerArc digital ignition system replacing the stock “bean can” timing tensioners, chains and gears, an updated ignition system and new valve covers. A completely new clutch assembly was installed, as were new cables and hoses, all with the familiar herringbone pattern to ensure consistency in appearance. To clean up the motor visually, Zack moved the battery to beneath the transmission and plumbed the carb intakes to draw air from the battery’s old location.

As the bike came back together, Zack installed a new wiring system fully serviceable by Haynes or Clymer wiring schematics and familiar to Airhead mechanics. Fully overhauled Bing 40mm carbs with new petcocks and fuel hoses matching all other hoses were installed. A two-into-one system made by Mac exhaust was also added, as were a new front brake master cylinder and rebuilt rear brake master cylinder with new EBC brake rotors and fully rebuilt Brembo brake calipers.

Polished chrome BUMM mirrors sit on Triumph Bonneville handlebars featuring Slash 2-style bar-end turn signals, while an H-type LED headlight bulb rests in a nacelle supporting a new headlight lens, reflector and trim ring. Vital information is relayed to the rider via a digital Acewell instrument gauge, while GIVI Corium soft saddlebags are mounted to a removable rack.

To Zack Witkowsky, the bike stays true to BMW factory engineering of the period and what a BMW Airhead is, but it also integrates modern technology that simply wasn’t available when the bike was built.

“I think it’s going to produce favorable opinions across the board from both older Airhead aficionados as well as newer riders.”

So far, the bike has received high praise from all who have seen it. It received an overwhelmingly positive response at the bike's unveiling at Motoworks in Chicago in late December. In the end, Zack believes, it will be ticket sales for the Foundation's Completely Custom Bike Raffle that will determine just how well the bike is accepted.

Regardless, Zack believes even his dad, who wasn't a Slash 2 or Slash 5 guy, would appreciate the bike and be proud of his son for taking an old, battered and beaten R 100 RT and building something this beautiful. In the unspoken language the father and son shared when they worked together, Zack believes he would have received an approving nod or grin, which would tell him everything he needed to know. Yet Zack says he didn't build the bike for anyone's approval but his own and to prove to himself, as well as potential clients of Blackwolf Touring and Custom, that he is indeed a mechanic and builder worthy of their trust.